Retrofits and Upgrades: How INGSOL Transforms Your Existing Industrial Machinery into High-Performance Assets

In today’s high-speed world of manufacturing, your industrial machinery is more than just equipment, it’s the beating heart of your operation. It’s what keeps your production lines moving, your products rolling out, and your promises to customers fulfilled. But here’s the truth: technology evolves fast. What once felt like the crown jewel of your plant can start feeling outdated, sluggish, or energy-hungry.

The usual reaction? Invest in brand-new machinery. But brand-new machines come with heavy price tags, long delivery timelines, production disruptions, and a steep learning curve for your workforce.

At INGSOL LLP, we’ve seen this scenario play out time and again. And we know there’s a smarter, faster, and far more cost-effective way to reclaim peak performance without breaking the bank.

Enter retrofits and upgrades. Our specialty lies in transforming your existing machines into powerful, efficient, and future-ready assets. Think of it as breathing new life into your reliable old workhorse turning it into a sleek, high-performance powerhouse without the stress of a full replacement.

For decades, we’ve partnered with top global brands, handling everything from dismantling and relocating massive machines to modernizing them for peak performance. Whether you’re working with Rotogravure printing presses, laminators, blown film lines, or slitting machines, our end-to-end solutions save you time, money, and stress.

In this blog, we’ll explore how retrofits and upgrades work, showcase INGSOL’s expertise, and explain why this approach is a game-changer for manufacturers like you searching for “industrial machinery retrofits” or “machine upgrade services.”

What Are Retrofits and Upgrades?

If you’re new to the concept, think of a retrofit as a strategic “makeover” for your machine. It’s like giving your car a major tune-up instead of buying a brand-new one. Retrofits focus on updating specific components to boost performance, enhance safety, or improve energy efficiency. For example, replacing outdated sensors with smart ones that detect issues before they cause downtime.

Upgrades, on the other hand, go a step further. They integrate entirely new technologies or features that weren’t even available when your machine was first built. Imagine adding IoT connectivity to monitor operations in real-time, or incorporating AI-driven controls for precision that’s off the charts.

Together, retrofits and upgrades bring your equipment up to modern standards meeting stricter environmental regulations, increasing output, and unlocking new levels of efficiency.

Why It Matters for Your Business

Here’s why retrofits and upgrades make sense:

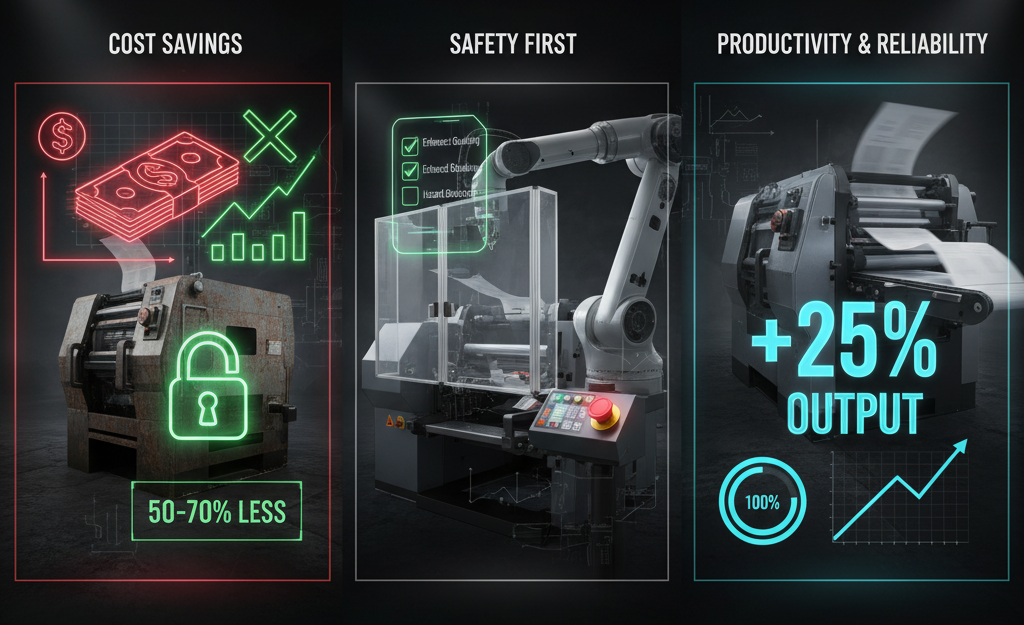

1. Cost Savings That Add Up: Brand-new machines can cost hundreds of thousands or even millions. Retrofits can slash that expense by 50–70%, targeting only what truly needs updating.

2. Quick Turnaround with Less Disruption: While full replacements might side line your line for weeks, our retrofits minimize downtime sometimes to just days.

3. Safety First: Older machines may not meet current safety codes. Upgrades add emergency stops, enhanced guarding, or automated hazard detection to protect your team and avoid costly fines.

4. Boosted Productivity and Reliability: Expect faster cycles, pinpoint accuracy, and fewer breakdowns. One client saw a 25% increase in output after we upgraded their printing press, numbers that directly hit the bottom line.

Retrofits and upgrades aren’t just “fixes”, they’re strategic investments to extend equipment life while keeping your operation competitive in industries like packaging, printing, and film production.

INGSOL’s Expertise in Retrofits and Upgrades

At INGSOL, we’re not just technicians, we’re problem-solvers with decades of hands-on experience. Our team has worked on everything from Cerutti and Bobst Rotogravure presses to W&H blown film lines, Rajoo extruders, and Rotomec laminators. Every project is customized to your machine’s quirks and your plant’s goals.

Let’s dive into some of our key areas of expertise:

1. Pneumatic Systems Modernization

Pneumatic systems power critical movements in many industrial machines but older setups can be riddled with issues: leaks that waste energy, sticky valves, and imprecise controls. These problems lead to unplanned shutdowns that eat into your profits.

We turn this around with a complete modernization. Starting with a full system audit, we identify hidden inefficiencies like air leaks that may be costing you thousands annually. We then overhaul pneumatic and electro-pneumatic components, replacing them with high-quality parts from brands like Festo, Aventics, Camozzi, and SMC.

The result? A more reliable, safer, and energy-efficient system often reducing air consumption by up to 30%. For example, on a recent Cerutti press project, we optimized lines and added smart sensors, achieving smoother operations and fewer maintenance calls.

If you’re searching “pneumatic system leaks in industrial machines,” our approach could be your game-changer.

2. Blown Film Line Overhauls

Blown film lines are the backbone of plastic film production, but they take a beating over time, clogged dies, worn parts, and misalignment can lead to quality issues.

Our process makes overhauls seamless. We clean and inspect die heads to remove build up that affects film quality, replace worn parts with OEM-equivalent or better components, and disassemble and reassemble modules with rigorous testing.

What sets us apart is our focus on startup readiness. We fine-tune until your line hums like new often achieving better bubble stability and thickness uniformity than before.

Take our work on Rajoo 5-layer lines: After overhaul, one client reported a 15% improvement in film quality, reducing waste and boosting yields. Searching “blown film line maintenance services”? This is how we keep your production rolling.

3. Printing Press and Laminator Upgrades

Printing presses and laminators are precision machines where even small issues like misregistration or inconsistent coatings can have huge impacts.

We’ve upgraded everything from full drive systems on Cerutti 9-color presses to pneumatic controls on Rotomec solvent-based laminators. Our upgrades restore machines to OEM specs (or better), integrating advanced tension controls, calibrating rollers for perfect alignment, and adding features like automatic web guiding.

Safety upgrades, such as enhanced guarding and emergency protocols, are always part of our package.

In one standout project, we transformed an aging Bobst press by modernizing its drives, resulting in faster print speeds and sharper colours, future-proofing the equipment against evolving industry standards.

If “Rotogravure printing press upgrades” is on your radar, our tailored solutions ensure your prints pop every time.

4. End-to-End Support

No retrofit is complete without strong support, and that’s where INGSOL excels.

- Tagging and Labelling for Precision: Every part is systematically tagged during dismantling, ensuring error-free reassembly.

- Operator Training On-Site: We train your team hands-on, covering new features and best practices.

- Troubleshooting and Commissioning: Post-install, we troubleshoot, fine-tune, and commission until everything’s optimized.

- Calibration to OEM Standards: We use state-of-the-art tools to calibrate to exact specs, guaranteeing reliability.

This holistic approach minimizes surprises and maximizes uptime, making us your go-to for “complete industrial machine retrofit services.”

Global Experience, Local Commitment

We’re not confined to one region, INGSOL has tackled projects across the UAE, Egypt, Saudi Arabia, and beyond. Our teams understand local regulations, logistics challenges, and cultural nuances, ensuring smooth execution anywhere.

Examples:

- Huhtamaki Flexible Packaging (UAE & Egypt): Dismantled, labelled, relocated, and reinstalled Cerutti and Bobst Rotogravure presses, Rotomec laminators, and B-Mec slitters—all with minimal downtime.

- Kangaroo Plastics (Saudi Arabia): Moved and recommissioned W&H 3-layer and Rajoo 5-layer blown film lines, complete with exhaustive testing.

- Abu Dhabi: Die head cleaning and reassembly for W&H and Rajoo machines led to flawless startups.

These aren’t just projects, they’re proof of our excellence in “global industrial machinery relocation and retrofits.” We’re global in reach but local in our dedication to your success.

Why Choose INGSOL for Your Retrofits?

In a crowded market, here’s what makes INGSOL different:

1. Proven Expertise: Years of experience with brands like Cerutti, Bobst, W&H, Rajoo, and Rotomec.

2. Dedicated Specialists: Mechanical and technical professionals passionate about delivering quality.

3. End-to-End Service: From assessment to handover, including dismantling, packaging, transport, reinstallation, and training.

4. Timely Delivery: We respect your deadlines, cutting downtime to get you back online fast.

5. Customized Solutions: Every retrofit is designed around your plant’s needs and goals.

Choosing us means partnering with a team that treats your machinery as if it were our own.

The Future of Manufacturing Starts with Smarter Machines

Upgrading isn’t about patching up the past; it’s about gearing up for the future. Rising energy costs, stricter emissions rules, and the push for smart factories all make retrofits a smart move.

At INGSOL, we’ve seen clients turn potential headaches into competitive advantages, lower costs, greener operations, and machines that perform like they’re fresh off the assembly line.

Conclusion

There you have it a deep dive into how retrofits and upgrades can revolutionize your manufacturing setup. Whether you’re battling outdated pneumatics, worn-out blown film lines, or finicky printing presses, INGSOL is here to help.

We’ve humanized the process, making it approachable and tailored to real-world needs all while delivering measurable ROI. If this resonates with your search for “affordable industrial machine upgrades” or “expert retrofits for printing presses,” let’s talk. Contact us today at INGSOL LLP to discuss how we can transform your assets.

Your high-performance future starts now, don’t wait for obsolescence to catch up!

References:

https://www.machinerylubrication.com/Read/31247/retrofitting-equipment-benefits

https://www.controleng.com/articles/upgrading-legacy-systems-for-modern-manufacturing/