Predictive Maintenance in Flexible Packaging Operations

In today’s competitive packaging industry, especially in flexible packaging operations, keeping machines running smoothly is critical. Equipment like blown film lines, which produce the films used for pouches, wraps, and bags, must operate efficiently to avoid costly breakdowns and production delays. This is where predictive maintenance comes in—a smarter, data-driven approach to keeping everything on track by fixing issues before they lead to major problems.

What is Predictive Maintenance?

Predictive maintenance uses technology to monitor machinery and predict potential failures before they happen. Unlike traditional maintenance, where repairs are scheduled at fixed intervals, predictive maintenance relies on real-time data from sensors that track performance. This means you can fix a problem before it causes an unexpected breakdown.

In flexible packaging operations, where continuous production is essential, predictive maintenance ensures machines like blown film lines and other packaging equipment run smoothly. By detecting issues early, businesses can avoid costly downtime and extend the life of their equipment.

Why is Predictive Maintenance Important in Packaging?

The packaging industry is fast-paced, and unexpected machine failures can result in missed deadlines and unhappy customers. With predictive maintenance, packaging machinery manufacturers can avoid such issues by identifying small problems before they become big ones.

For example, a blown film line used in flexible packaging may experience gradual wear and tear over time. By using predictive maintenance, sensors can detect changes in machine performance—like unusual vibrations or temperature changes—so repairs can be made before the equipment fails.

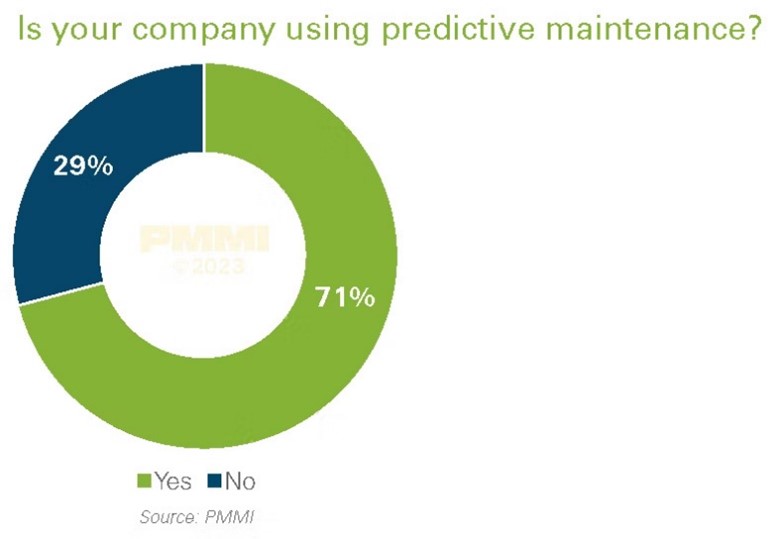

As per a recent survey by PMMI, “Sustainability and Technology – The Future of Packaging and Processing”, over 70% of respondents stated that their company was utilising predictive maintenance technology including Cloud based vibration monitoring, AI-based data analytics & online tracking. Existing systems such as Manufacturing Execution Systems (MES) or Total Productive Maintenance (TPM), were also being used by executives to monitor the effects of predictive maintenance on their operations.

Key Benefits of Predictive Maintenance

- More Uptime, Less Downtime– One of the biggest benefits of predictive maintenance is minimizing unplanned downtime. For large scale packaging machines, even a few hours of downtime can lead to significant losses. Predictive maintenance allows companies to schedule repairs at convenient times, ensuring machines stay up and running longer.

- Cost Savings- Predictive maintenance can significantly reduce repair and replacement costs. Rather than dealing with emergency breakdowns that require expensive fixes, companies can address potential issues before they escalate. Plus, fixing a small problem early is always cheaper than waiting for a major failure.

- Extend Equipment Lifespan By identifying problems early and addressing them promptly, predictive maintenance extends the lifespan of packaging machinery. This means fewer expensive replacements of critical equipment like blown film lines and other machines used in flexible packaging production.

- Optimized Maintenance Schedules– Instead of sticking to a fixed maintenance schedule, predictive maintenance ensures repairs happen only when necessary. This allows businesses to plan better and focus on what needs immediate attention, freeing up resources and personnel for other tasks.

How Predictive Maintenance Works

Predictive maintenance relies on sensors that monitor key performance indicators such as temperature, pressure, and vibration. In packaging machinery, especially blown film lines, these sensors track how the equipment is performing. If something seems off—like a slight increase in temperature or unusual vibrations—the system flags it for inspection.

This data is analyzed using advanced software, often with the help of machine learning or artificial intelligence (AI), to predict when failures might occur. This way, maintenance teams can perform repairs at the right time—before a full-scale breakdown happens.

Application in Blown Film Lines

Blown film lines, which are essential to flexible packaging operations, benefit significantly from predictive maintenance. These machines produce plastic films for a wide range of products, and they operate under intense conditions with tight tolerances. Even minor mechanical issues can impact product quality and production rates.

Predictive maintenance helps detect early signs of wear in critical components like the extruder, cooling systems, or winders. By catching these issues early, companies can maintain high product quality, reduce scrap rates, and ensure that production runs smoothly.

Why Packaging Companies Should Embrace Predictive Maintenance

As the demand for flexible packaging continues to rise, businesses need to adopt modern technologies that improve efficiency. Predictive maintenance is one such tool, offering a way to keep machines running at their best while lowering the risk of costly disruptions.

For OEMs and machinery manufacturers, adding predictive maintenance features to their equipment is becoming a key selling point, giving their products an edge in the marketplace. The need for OEMs to work with predictive maintenance is arising day by day, to design end to end predictive maintenance solutions that can monitor product changeover processes.

Conclusion

Predictive maintenance is a game-changer for the packaging industry. By using technology to predict when machines like blown film lines need maintenance, businesses can minimize downtime, reduce costs, and extend equipment life. For companies involved in flexible packaging, adopting predictive maintenance is not just a smart move—it’s becoming essential to stay competitive.

In the fast-evolving world of packaging, its essential for packaging companies and machinery manufacturers to employ a trustable predictive maintenance partner who can understand their specific needs and requirements. At INGSOL, we provide complete predictive maintenance solutions to ensure your machines function without experiencing downtime, and our expert technical team is available 24X7 to help and support as and when required.

References –

Img links –