Flexible Packaging: The Key Trends and Highlights from 2024

The flexible packaging industry has witnessed remarkable growth in 2024, driven by evolving consumer demands, technological advancements, and sustainability goals. As companies across sectors—especially food, pharmaceutical, and industrial manufacturing—seek cost-effective, lightweight, and customizable packaging options, flexible packaging has emerged as a preferred solution. Here’s a look at the key trends and innovations reshaping this dynamic sector.

1. Sustainability: A Core Priority

In 2024, sustainability has remained a dominant trend in the packaging industry. Brands are shifting towards recyclable, biodegradable, and compostable packaging materials to meet consumer and regulatory demands. Circular economy initiatives encourage manufacturers to reduce plastic waste by investing in eco-friendly packaging machinery capable of handling bio-materials efficiently. Companies are also actively working to eliminate greenwashing practices, ensuring transparency in their sustainability efforts.

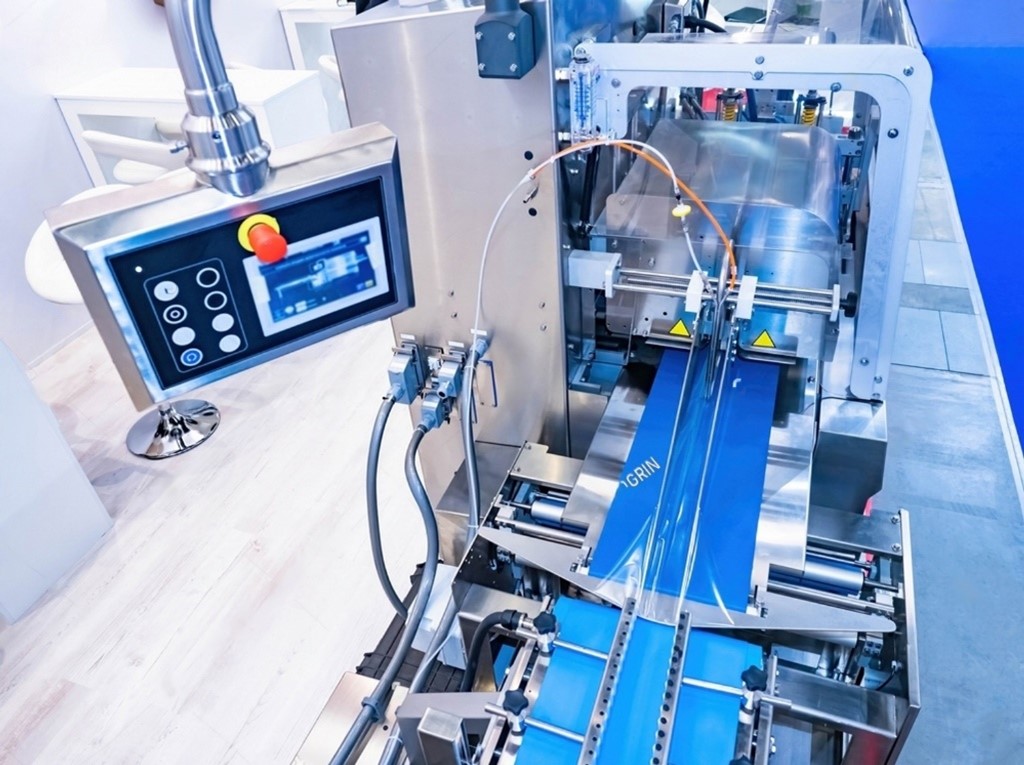

2. Technological Advancements in Packaging Machinery

The latest advancements in packaging machinery are enabling faster production with fewer errors. Automation, Predictive maintenance and smart packaging solutions are becoming standard, allowing manufacturers to improve efficiency. New machinery manufacturers and OEMs are focusing on integrating IoT sensors and artificial intelligence, including Cobots, Vision systems, Automated Guided Vehicles and 3D Printing. Further, the implementation of AI into packaging machines have enabled a more agile and responsive packaging process, ensuring increased production speeds and minimizing operational costs.

3. Increased Adoption of Blown Film Technology

The demand for blown film lines has surged in 2024, particularly in the food and beverage sectors. These lines offer excellent flexibility and cost-efficiency, allowing manufacturers to create thin plastic films with high durability. Innovations in this space have focused on reducing energy consumption and minimizing the environmental impact of production, which aligns with sustainability goals.

4. Growth Driven by E-commerce and Consumer Demand

With the expansion of e-commerce, the need for durable yet lightweight packaging has become critical. Flexible packaging offers the perfect solution, providing both protection and portability. Manufacturers are also exploring customized printing technologies to enhance branding and customer engagement through smart packaging solutions—such as QR codes integrated into packaging for better tracking and interaction.

5. Collaborations Between OEMs and Packaging Manufacturers

Partnerships between OEMs, machinery manufacturers, and packaging firms are fueling industry innovation. These collaborations are helping businesses develop packaging that meets specific industry requirements—whether it’s packaging for pharmaceuticals that needs to ensure product integrity or flexible films for perishable food items. Tailored packaging solutions have become a competitive advantage in sectors like healthcare and food manufacturing

6. Regulatory Compliance and Packaging Standards

Governments worldwide are imposing stricter regulations on packaging waste management. Few important regulations like the UN’s Global Plastics Treaty and the EU’s PPWD revision continue to reshape the landscape of the packaging industry. Compliance with these regulations has prompted companies to invest in advanced machinery that can process eco-friendly materials without compromising on production efficiency.

How INGSOL Supports the Flexible Packaging Industry

At INGSOL, we understand the evolving needs of the packaging industry and offer industry leading solutions for packaging & Printing machines including Rotogravure & Flexographic, along with services & solutions for Lamination machines, Metallizer, Slitter & Extrusion coating machines. Our extensive variety of spare parts & consumables along with retrofits & upgrades supported by our goal for maximum customer success ensures minimal hindrances and maximum production for our clients. From installation to maintenance, our expert service engineers ensures that our products and services exceed client expectations.

Looking for innovative packaging solutions? Connect with INGSOL and let us help your business thrive with cutting-edge technology and sustainable practices.