Introduction: The Age of Intelligent Manufacturing

The manufacturing world stands at the intersection of innovation and transformation. The integration of data, machines, and intelligence is no longer an aspiration but it’s the foundation of industrial progress.

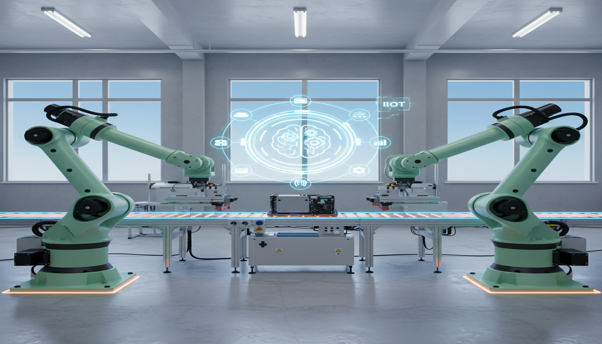

The Industrial Internet of Things (IIoT) has emerged as the driving force behind this evolution, empowering manufacturers to operate with precision, agility, and foresight.

As global competition intensifies and customer expectations evolve, the key differentiator for manufacturers lies in how effectively they harness real-time data. From improving asset utilization to ensuring production continuity, IIoT technologies are redefining every link in the manufacturing value chain.

At the forefront of this revolution is INGSOL, offering next-generation IIoT solutions designed to transform challenges into opportunities and operations into intelligent ecosystems.

The Manufacturing Landscape Today

The manufacturing industry has always been a symbol of progress and productivity. Yet in recent years, the pace of change has accelerated beyond traditional boundaries.

Automation, robotics, and digital integration have become core pillars of modern production systems. However, the real transformation lies in how data is being utilized not just collected, but interpreted, connected, and acted upon.

Today’s manufacturers face a rapidly evolving environment characterized by:

- Increasing demand for customized products

- Tightening margins and cost pressures

- The need for faster decision-making and flexible production

- Growing emphasis on sustainability and energy efficiency

While traditional automation achieved process consistency, it often fell short of delivering real-time adaptability.

That’s where IIoT steps in, enabling manufacturers to bridge the gap between operations and intelligence, connecting every asset, process, and system through seamless digital integration.

The Core Challenges Manufacturers Face

Despite technological progress, many manufacturers still grapple with persistent challenges that limit productivity and growth.

- Unplanned Downtime: Unexpected equipment failures disrupt production schedules and inflate maintenance costs.

- Limited Visibility: Fragmented systems and siloed data make it difficult for leaders to view operations holistically.

- Inefficient Resource Utilization: Without accurate performance data, optimizing energy, materials, and labour becomes reactive rather than strategic.

- Complex Supply Chains: Expanding global networks demand real-time tracking and synchronization across multiple facilities.

- Data Overload Without Insight: Vast amounts of factory data remain untapped, collected but never translated into action. These challenges call for more than incremental fixes; they demand a connected, intelligent ecosystem that can predict, adapt, and evolve.

What Is IIoT and Why It Matters

The Industrial Internet of Things (IIoT) combines operational technology (OT) and information technology (IT) to create a unified, data-driven manufacturing environment.

Through sensors, smart devices, and connectivity, IIoT allows factories to collect, analyze, and act on data in real time. This connectivity transforms traditional plants into smart factories, agile, adaptive, and insight-led.

IIoT enables:

- Predictive Maintenance: Anticipating issues before they disrupt production.

- Optimized Processes: Continuous improvement driven by data analytics.

- End-to-End Visibility: Unified monitoring from the shop floor to executive dashboards.

The real value of IIoT lies in turning information into intelligence and this is where INGSOL makes a difference.

How INGSOL’s IIoT Solutions Bridge the Gap

INGSOL’s IIoT ecosystem is designed to turn industrial data into operational excellence.

By integrating advanced analytics, cloud-edge connectivity, and intuitive dashboards, INGSOL empowers manufacturers to make smarter, faster decisions.

- Comprehensive Connectivity: Seamless integration connects every machine, device, and sensor enabling continuous data flow and unified visibility.

- Predictive Insights: INGSOL’s analytics engine forecasts potential equipment issues before they occur, minimizing unplanned downtime.

- Optimized Operations: Real-time insights allow dynamic optimization of throughput, energy consumption, and process performance.

- Scalable and Flexible Architecture: Whether managing one facility or a global network, INGSOL’s IIoT framework scales efficiently to meet evolving business needs.

- Real-Time Decision Support: Intelligent dashboards deliver live insights empowering leaders to make data-backed decisions instantly.

Key Capabilities and Innovations of INGSOL IIoT

INGSOL’s IIoT platform offers a comprehensive suite of tools to drive industrial transformation:

- Asset Health Monitoring: Continuous diagnostics ensure early detection of faults and prolonged equipment life.

- Energy Management: Intelligent tracking identifies inefficiencies and promotes sustainable operations.

- Production Analytics: Actionable insights enhance output, yield, and quality control.

- Condition-Based Maintenance: Maintenance is performed only when required based on live machine data.

- Cloud + Edge Integration: Secure, hybrid processing ensures reliability and data integrity across all levels.

- Customizable Dashboards: User-specific interfaces provide clarity for every role from operators to top management.

Together, these capabilities turn static data into dynamic intelligence, making manufacturing smarter, safer, and more sustainable.

Real-World Impact: Smarter, Leaner, Faster Operations

The transformation achieved through INGSOL’s IIoT solutions is measurable and meaningful. Manufacturers experience:

- Higher Productivity: Real-time monitoring minimizes idle time and enhances throughput.

- Cost Efficiency: Predictive maintenance reduces unnecessary repairs and resource waste.

- Superior Quality: Data-backed insights drive precision and consistency in every production cycle.

- Sustainability: Optimized energy consumption supports green manufacturing goals.

- Empowered Workforce: Teams make proactive decisions based on accurate, live data.

By merging intelligence with execution, INGSOL helps organizations unlock the full potential of their operations.

The Future of Manufacturing with INGSOL

The next decade of manufacturing belongs to the intelligent, integrated enterprise.

As digital ecosystems evolve, IIoT will serve as the foundation for autonomous, adaptive, and resilient factories.

With INGSOL’s forward-thinking approach, manufacturers can expect:

- AI-driven process optimization

- Seamless human-machine collaboration

- Sustainable production ecosystems

- End-to-end traceability and transparency

As industries move toward Industry 5.0, INGSOL continues to lead with innovation that bridges technology and human intelligence, creating environments that think, learn, and grow with every process.

Conclusion

Manufacturing is no longer about mass output, it’s about smart, sustainable, and scalable production.

With INGSOL’s IIoT solutions, industries gain the power to predict, prevent, and perform at their peak.

By connecting machines, data, and intelligence, INGSOL enables enterprises to transition from reactive management to proactive transformation.

The result?

An ecosystem that is efficient, adaptive, and ready for the future.

References:

https://www.sciencedirect.com/science/article/pii/S0736584524000553?utm_

https://www.twi-global.com/technical-knowledge/faqs/industry-5-0?utm_