Why Industrial Automation Is No Longer Optional in 2025

The global manufacturing environment is changing at an unprecedented pace. Rising labour costs, skilled worker shortages, shrinking profit margins, unstable supply chains, and strict sustainability compliance have forced industries to rethink traditional operations. Manual processes are no longer enough, companies that fail to modernize are quickly losing competitive ground.

Recent studies support this shift. McKinsey reports that highly automated plants can achieve between 30%–50% higher labour productivity and 15%–30% lower operating costs compared to conventional factories. Gartner predicts that by the end of 2025, 85% of major manufacturing companies will have adopted smart automation systems. At the same time, the global industrial automation market is projected to exceed $410 billion by 2028, showing massive demand and accelerated adoption.

No matter the scale whether a small fabrication unit or a multi-plant industrial conglomerate, industrial automation services have become the most reliable way to increase efficiency, profitability, safety, and long-term sustainability.

Introduction to Industrial Automation

What Is Industrial Automation?

Industrial automation refers to the use of control systems, robotics, intelligent sensors, software platforms, and data technologies that allow machinery and industrial processes to operate with minimal human involvement. The primary objectives include higher speed, superior consistency, enhanced worker safety, increased traceability, and data-backed decision-making.

Modern automation is not about replacing humans, but about enabling them to work smarter while intelligent systems handle repetitive, hazardous, or highly precise tasks.

The Evolution of Automation to Industry 5.0

Industrial automation has evolved across multiple phases:

- The journey began with steam-powered mechanization in the late 18th century.

- Henry Ford revolutionized mass production with the moving assembly line in 1913.

- The invention of the programmable logic controller (PLC) in 1969 accelerated automation.

- The concept of Industry 4.0 emerged around 2011, integrating cyber-physical systems, AI, IoT, and data analytics.

- By 2025, we are now entering Industry 5.0, where human creativity and intelligent automation systems work collaboratively with a strong focus on sustainability, personalization, and resilience.

.Why Automation Is Urgently Needed Today

Industrial automation has become essential due to several factors:

- Global skilled labour shortages may reach 85 million workers by 2030.

- Demand for product customization has increased significantly.

- ESG compliance and net-zero carbon commitments are becoming mandatory.

- Global supply chain disruptions require agile, responsive production.

Automation ensures continuity, competitiveness, and profitability in an unstable industrial climate.

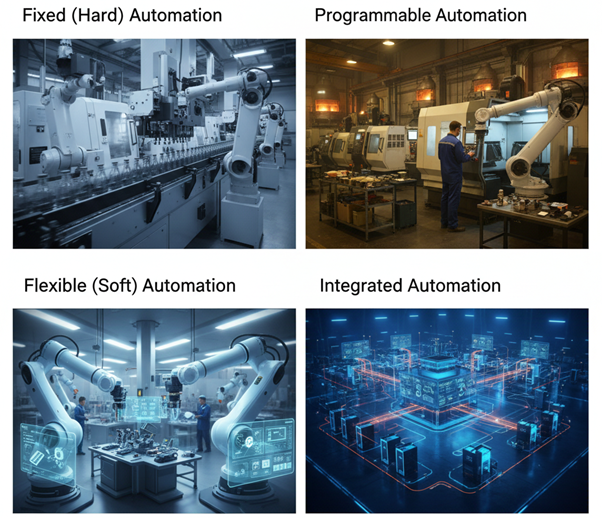

Types of Industrial Automation Systems

There are four core categories of industrial automation systems, each designed for different production needs:

- Fixed (Hard) Automation:

Used in extremely high-volume, repetitive manufacturing such as bottling, packaging, and transfer lines. It offers low cost per unit and very high throughput but provides almost no flexibility for product changes. - Programmable Automation:

Ideal for batch processes where the same equipment is used to produce different items. Examples include CNC machines, paint booths, and industrial furnaces. Reprogramming requires moderate effort and time, making it suitable for medium-scale production. - Flexible (Soft) Automation:

Designed for high product variability and rapid changeovers. With robots, AI-enabled vision systems, and modular tooling, changeovers can occur in minutes. This system suits modern personalized manufacturing demands. - Integrated Automation:

Combines hardware, software, IT/OT connectivity, MES, ERP, and cloud platforms into a single digital ecosystem. This is the foundation of true smart factories and Industry 4.0 operations

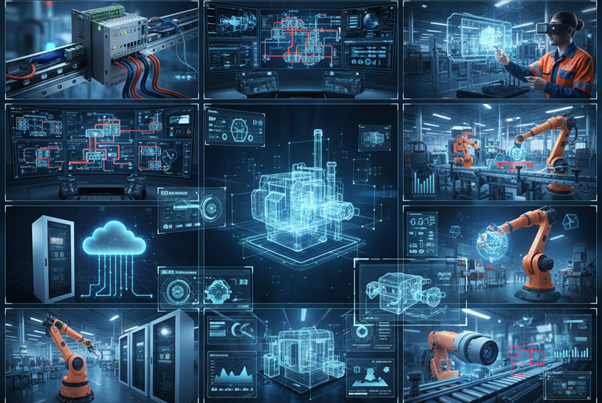

Key Technologies Powering Modern Automation in 2025

Modern automation ecosystems are built on advanced integrated technologies including:

- Programmable Logic Controllers (PLCs) and edge controllers for real-time control.

- SCADA systems and data historians for visualization, alarms, analytics and remote monitoring.

- Distributed Control Systems (DCS) for large-scale continuous operations such as refineries and power plants.

- Human-Machine Interfaces (HMIs) including modern touch panels, remote dashboards, and augmented-reality displays.

- Industrial Internet of Things (IIoT) platforms enabling plant-wide connectivity.

- Robotics and collaborative robots (cobots) that work safely alongside humans.

- Machine vision and AI-enabled automated quality inspection.

- Digital twins that simulate real production assets and predict future behaviour.

- Predictive maintenance software using AI to diagnose issues before breakdowns occur.

Together, these technologies enable more intelligent, self-optimizing, and resilient manufacturing.

Industrial Automation Services -What Companies Actually Receive

Professional automation service providers deliver far more than equipment installation. The service portfolio includes:

- Consulting, feasibility assessment, audits, and ROI calculations.

- Engineering design including FEED, P&IDs, control architecture, and functional specifications.

- Custom control panel design and fabrication to UL508A/IEC standards.

- Complete PLC, SCADA, DCS, and safety-instrumented system programming.

- HMI and SCADA interface development with mobile and web access capability.

- Legacy modernization and system upgrades with seamless integration.

- MES and ERP connectivity for full digital traceability.

- Industrial cybersecurity aligned with IEC 62443 and zero-trust principles.

- AI-based predictive maintenance and remote monitoring solutions.

- Operator training, documentation, and long-term maintenance contracts.

Real-World Applications Across Major Industries

Industrial automation is transforming multiple verticals. For example:

- Automotive plants deploy fleets of robots guided by 3D vision to weld, assemble, and inspect vehicles on mixed-model production lines.

- Food and beverage plants run fully automated packaging and clean-in-place (CIP) systems achieving extremely high hygiene and uptime levels.

- Pharmaceutical facilities use robotic sterile filling lines compliant with 21 CFR Part 11 and Annex 1 standards.

- Oil and gas companies use SCADA platforms to monitor pipelines and production assets spread across thousands of kilometres.

- Renewable energy operations apply predictive analytics to wind turbines, improving energy yield by up to 15%.

- Modern warehouses use autonomous mobile robots (AMRs) that increase order fulfilment speed by two to three times.

Quantifiable Benefits of Industrial Automation

Factories adopting automation typically achieve measurable improvements such as:

- 15%–35% increase in Overall Equipment Effectiveness (OEE)

- 30%–50% increase in labour productivity

- 70%–95% reduction in quality defects

- Up to 72% reduction in workplace accidents

- 10%–25% reduction in energy use

- 25%–40% lower maintenance costs through predictive maintenance

- 20%–30% reduction in inventory and working capital

Most companies achieve full return on investment within 18 to 36 months.

Common Challenges and Practical Solutions

While automation offers huge advantages, some challenges may arise. These can be addressed effectively:

- High initial investment can be managed through phased deployment or subscription-based Automation-as-a-Service models.

- Skilled workforce shortages can be resolved through advanced training, vendor academies, and no-code platforms.

- Cybersecurity risks can be controlled with IEC 62443 compliance and zero-trust security frameworks.

- Integration of legacy systems can be simplified using middleware, OPC-UA gateways, and staged migrations.

- Organizational resistance can be overcome through strong change management and quick-win pilot projects demonstrating value.

Future Trends That Will Dominate 2025 to 2030

Over the next few years, industrial automation will be shaped by several disruptive innovations including:

- Fully autonomous robot fleets controlled through AI orchestration.

- Generative AI capable of programming automation code automatically.

- Private 5G networks enabling ultra-low latency communication.

- Digital twins used to simulate and reduce real-time carbon footprint.

- Augmented-reality headsets that assist technicians without prior training.

- Swarm robotics for collaborative synchronized assembly operations.

- Early applications of quantum computing for supply-chain optimization.

How to Choose the Right Industrial Automation Service Provider in 2025

While selecting an automation partner, consider the following key factors:

- At least 10 to 15 years of experience in your specific industry segment.

- Proven history of brownfield modernization and successful project delivery.

- Official partnerships with manufacturers such as Siemens, Rockwell, ABB, Schneider, Mitsubishi, and others.

- Certifications including ISO 9001, ISO 27001, UL-508A, TUV Functional Safety, and IEC 62443 cybersecurity.

- Strong after-sales support teams with guaranteed service response time under four hours.

- Flexible pricing models such as fixed-price, performance-linked, or subscription.

- Financial strength and insurance coverage to support mission-critical installations.

Conclusion

Industrial automation is no longer a supplementary upgrade, it is the central strategy for creating future-ready, resilient, and profitable manufacturing systems. The evolution from isolated machines to intelligent digital ecosystems has proven its ability to enhance performance dramatically in terms of efficiency, safety, sustainability, and cost optimization.

In 2025 and beyond, the companies that succeed will be the ones that treat automation as the heart of innovation and a powerful competitive differentiator not just an expense.

The technology is mature, the ROI is proven, and expert partners are available to guide transformation.

The best time to modernize your manufacturing ecosystem is now.

Do not wait for competitors to take the lead.

Schedule a professional automation assessment this quarter and start building the intelligent industrial future your organization deserves.

Reference:

https://www.machinemetrics.com/blog/industrial-automation?.com