How Solar Energy is Powering the Future of Packaging Machinery Manufacturing

The packaging industry is evolving rapidly, and sustainability is now at the forefront of manufacturing decisions. One of the most effective ways to reduce environmental impact while cutting operational costs is integrating solar energy into packaging machinery manufacturing. Companies across the globe are investing in solar-powered solutions to enhance efficiency, meet sustainability goals, and comply with regulatory changes.

Why Solar Energy in Packaging Machinery Manufacturing?

Manufacturing packaging machinery is an energy-intensive process. From metal fabrication to assembly lines, a significant amount of electricity is required to run machines, heat components, and test finished products. Traditionally, this energy comes from fossil fuels or conventional power grids, contributing to carbon emissions and increasing operational costs. Solar energy offers a practical alternative with multiple advantages:

- Lower Energy Costs: Solar panels generate electricity at a lower long-term cost than grid-based energy.

- Reduced Carbon Footprint: Switching to solar significantly cuts greenhouse gas emissions, helping companies achieve sustainability targets.

- Energy Independence: Solar power reduces reliance on fluctuating electricity prices and potential power outages.

- Government Incentives: Many countries offer subsidies, tax credits, and grants for industries adopting renewable energy.

Automation for Improved Efficiency and Reduced Costs

1. Solar-Powered Manufacturing Plants

Many packaging machinery manufacturers are installing solar panels on factory rooftops to generate electricity for their production lines.

- Case Study: Tetra Pak’s Solar Initiatives

Tetra Pak, a global leader in food packaging, has committed to sourcing 100% renewable electricity for its operations. The company has installed solar panels at multiple manufacturing facilities worldwide, reducing dependence on fossil fuels and cutting operational costs. - Example: SIG Combibloc’s Solar-Powered Plants

SIG, a major player in aseptic carton packaging, has integrated solar power into its manufacturing plants. Their factory in China runs partially on solar energy, demonstrating a commitment to reducing environmental impact while maintaining efficiency.

2. Solar-Powered Machinery and Equipment

Advancements in solar panel efficiency and energy storage have enabled the direct use of solar power in running packaging machinery.

- Example: Solar-Powered Conveyor Belts

Some packaging plants now operate conveyor belts and sealing machines using solar-generated electricity. This reduces peak-hour energy demand and improves overall efficiency. - Solar-Powered Air Compressors

Air compressors, essential in packaging machinery for pneumatic functions, are being powered by solar energy to cut energy costs while maintaining high-performance levels.

3. On-Site Solar Farms for Large-Scale Operations

Instead of relying solely on rooftop solar panels, larger manufacturers are investing in dedicated solar farms to power their entire production processes.

- Case Study: Nestlé’s Solar-Powered Packaging Plant

Nestlé has developed solar farms in several locations to power its packaging operations. In its Australian plant, solar energy is being used to run packaging lines for bottled water and food products. - Example: Coca-Cola’s Solar Installations

Coca-Cola has installed solar panels in multiple bottling and packaging facilities worldwide, aiming to achieve net-zero carbon emissions.

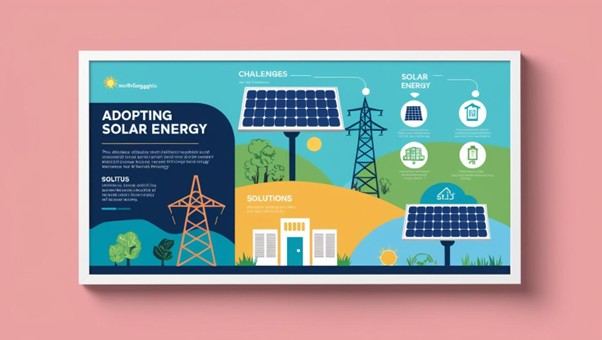

Challenges and Solutions in Adopting Solar Energy

While the benefits of solar energy in packaging machinery manufacturing are evident, some challenges exist:

- Initial Investment Costs: Setting up solar power infrastructure requires significant upfront capital. However, long-term savings and government incentives make it a financially viable option.

- Energy Storage Limitations: Since solar energy is not available at night, manufacturers need efficient battery storage solutions. Lithium-ion and flow batteries are increasingly being used to store excess solar energy.

- Space Requirements: Solar panels require adequate space, which might be a challenge for some manufacturing facilities. This is being addressed with innovative solar roofing solutions and floating solar panels.

- Initial Investment Costs: Setting up solar power infrastructure requires significant upfront capital. However, long-term savings and government incentives make it a financially viable option.

The Future of Solar Energy in Packaging Machinery

The trend toward solar-powered packaging machinery manufacturing is expected to grow in the coming years. With increasing technological advancements, declining solar panel costs, and global sustainability initiatives, more companies will transition to renewable energy sources.

Innovations such as solar-powered robotic arms, AI-driven energy optimization, and smart grid integration will further enhance the efficiency of solar-powered packaging plants. Additionally, collaborations between packaging manufacturers and renewable energy providers will lead to more streamlined solutions for energy management.

Conclusion

Solar energy is no longer an experimental concept in the packaging industry—it is a practical and cost-effective solution for manufacturers looking to reduce carbon footprints and operational costs. As more companies invest in solar-powered manufacturing plants, machinery, and equipment, the future of packaging looks brighter and more sustainable. With governments pushing for greener initiatives and customers demanding eco-friendly products, integrating solar energy into packaging machinery manufacturing is a step in the right direction.

References:

https://www.investindia.gov.in/blogs/indias-solar-power-revolution-leading-way-renewable-energy

https://ficuspax.com/blog/advancing-solar-panel-packaging-exploring-future-trends-and-innovations/