The Role of Automation in Packaging

The packaging industry has undergone significant transformation over the last few years, with automation playing a pivotal role in driving efficiency and innovation. From reducing labor costs to enhancing precision and productivity, automation is reshaping how packaging machinery operates. In a competitive global marketplace, Original Equipment Manufacturers (OEMs) and machinery manufacturers are increasingly seeking automation technologies to stay ahead, streamline production, and meet the growing demands for packaging solutions.

The Evolution of Automation in Packaging

Today, advanced technologies enable intelligent packaging machinery to adapt, learn, and optimize processes in real time. For example, smart sensors embedded in machinery can now collect vast amounts of data, providing actionable insights to improve production efficiency and reduce downtime.

Packaging automation has also embraced machine learning and artificial intelligence, allowing machines to detect anomalies, forecast maintenance needs, and minimize waste. These systems are particularly beneficial for machines like blown film lines, where precision and speed are crucial to maintaining high-quality standards for blown film production.

Key Automation Technologies in Packaging

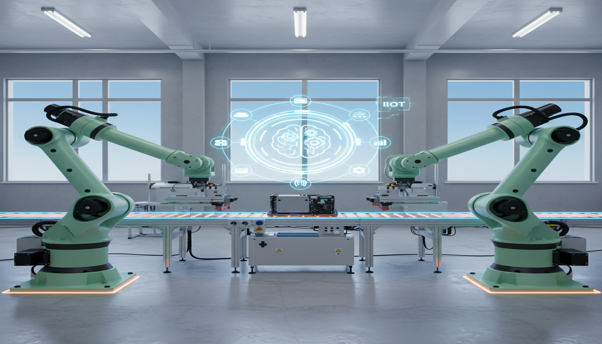

1. Robotic Systems: Robotic arms and pick-and-place systems are widely used in automated packaging lines. These machines can handle delicate tasks such as sorting, packing, and labeling at speeds far beyond human capabilities. Robotic solutions are highly flexible, making them ideal for industries producing varying packaging designs and sizes.

2. Collaborative Robots (Cobots): Cobots are designed to work alongside humans, providing support in complex or repetitive tasks. Their ease of integration into existing packaging lines and user-friendly programming make them a popular choice among OEMs and packaging machinery manufacturers.

3. Automated Guided Vehicles (AGVs): AGVs have revolutionized how materials are moved within packaging facilities. These self-guided vehicles transport raw materials, semi-finished goods, and packaged products with minimal human intervention, allowing for seamless integration into highly automated manufacturing environments.

4. Blown Film Line Automation: In flexible packaging, automation in blown film lines is crucial. Precision in controlling the film thickness, temperature, and cooling process ensures consistent quality. Automated systems allow machinery to adjust parameters in real-time based on feedback from sensors, resulting in faster production cycles and less waste.

Other major components/systems like Safety input module, Analog module, I/O modules, mixed modules & digital I/Os along with other digital and analog modules are mostly used in the automation of packaging production processes.

Challenges in Automating Packaging Processes

While the benefits of automation in packaging are clear, OEMs and machinery manufacturers face a set of challenges in fully automating their packaging processes.

- Cost of Implementation: Upgrading to advanced automation technologies requires significant upfront investment. For many manufacturers, especially smaller players in the packaging industry, the costs of adopting new systems, training personnel, and maintaining these technologies can be prohibitive.

- Complexity in Integration: Integrating new automation technologies with existing packaging machinery can be complex. This often involves modifying existing workflows, reprogramming machines, and ensuring compatibility between different systems.

- Maintaining Flexibility: Packaging manufacturers are required to produce a variety of packaging designs and materials, particularly with the rise of flexible packaging. Automation systems must be adaptable to handle this variety while maintaining efficiency. The challenge lies in designing systems that are both highly productive and versatile enough to meet market demands.

The Need for Automation in Packaging Machinery Processes

The need for automation in packaging processes has never been more critical. With increasing consumer demand for faster production, reduced costs, and eco-friendly packaging, manufacturers must continually find ways to improve efficiency. Automation provides a solution by allowing packaging machinery to operate around the clock, reducing labor costs, and improving overall production accuracy.

Moreover, automated systems are more capable of meeting stringent regulatory requirements, such as sustainability standards, by minimizing waste and optimizing resource usage.

Automation Solutions by INGSOL

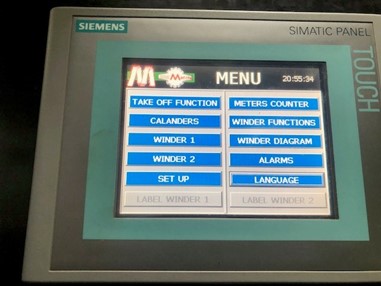

At INGSOL, we understand the challenges faced by OEMs and manufacturers in the packaging industry. We offer complete drive solutions, machine-human interface (HMI) systems, and customized programming for automating packaging machinery processes. Whether you are looking to enhance the performance of your blown film lines or automate your packaging process and production, INGSOL provides tailored solutions to improve efficiency, productivity, and sustainability.

Contact us today for knowing how we can help you automate your packaging processes –

9205888252 , 9311487878 | sales@ingsol.in

References –

- http://surl.li/xohlhi

- http://surl.li/vjwjkk

- http://surl.li/psnuix

- http://surl.li/novami

- http://surl.li/sshmqv

Images –

- http://surl.li/ampwov