Underlying technologies of packaging system

Active packaging: Active packaging, a progressive departure from conventional methods, responds to shifting consumer demands and market dynamics. This innovative food-packaging approach incorporates elements that can release or absorb substances, preserving food quality and extending shelf life. Key benefits of active packaging for perishable goods include reduced active substance usage, minimized particle migration, and the elimination of potential bacterial contamination from industrial processes. Components often integrated into active packaging systems include oxygen and ethylene scavengers, flavour modifiers, antimicrobial agents, and antioxidants.

Intelligent Packaging: Intelligent packaging system use communication functions to facilitate decision-making aimed at preserving food quality, extending shelf life and improving overall food safety. It executes functions like sensing, detecting, tracing, recording, and transmitting specific data. Key components encompass time-temperature indicators, gas detectors, freshness/ripening indicators, and RFID systems. Indicators and sensors relay essential information, signalling changes in factors such as temperature or ph.

Smart Packaging: Smart packaging offers a comprehensive solution that intelligently monitors product and environmental changes while proactively responding to them. It deploys chemical sensors and biosensors to ensure food quality and safety from production to consumption. This technology employs an array of sensors, detecting factors like freshness, pathogens, leaks, carbon dioxide, oxygen, pH levels, time, and temperature. The specific capabilities of smart packaging systems adapt to the nature of the product, whether it’s food, beverages, pharmaceuticals, or various other goods. Likewise, the conditions monitored, communicated, or adjusted align with product requirements

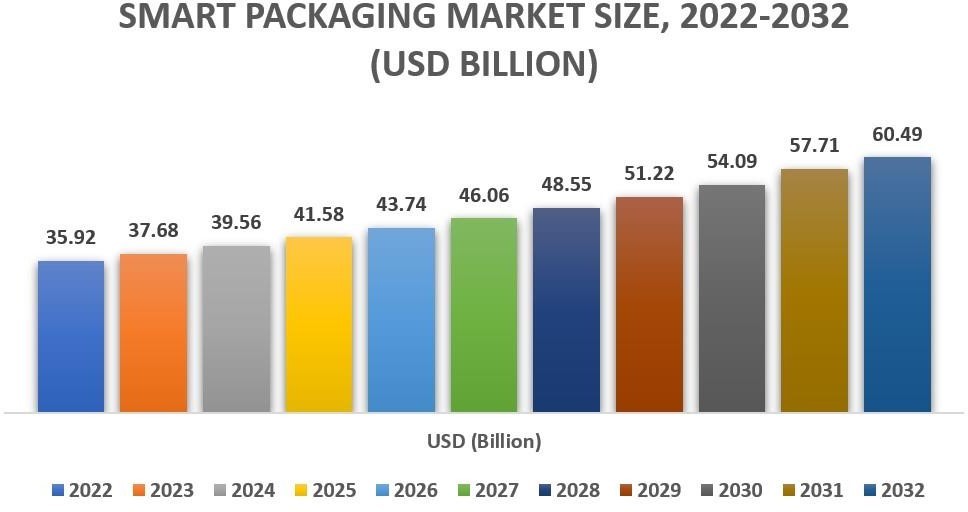

The worldwide smart packaging market is poised to reach a substantial $60.49 billion by 2032. Smart packaging encompasses innovative packaging systems that incorporate embedded sensor

technology, primarily employed in sectors such as food, pharmaceuticals, and various other product categories. Its applications span from prolonging shelf life, monitoring freshness, conveying quality information, to enhancing product safety and customer well- being.

Furthermore, smart packaging doesn’t merely serve as a technological advancement but also unlocks novel business prospects rooted in the realm of digitization, seamlessly aligning with the broader scope of Industry 4.0. Embracing this dynamic sector offers companies a unique gateway to innovation and growth in the ever-evolving landscape of modern industry.

CHALLENGE

Antimicrobial Packaging and Innovations:

Antimicrobial packaging is a rising interest within both the research and industrial sectors, with the potential to enhance product quality and safety. Research in microbial active packaging should increasingly focus on naturally-derived antimicrobial agents, bio-preservatives, and biodegradable solutions. Innovations in biodegradable packaging have already showcased improved quality and safety, affirming the viability of bio-active components. The development of active materials that preserve their mechanical and barrier properties is essential, further elevating food safety and shelf life.

Thin Film Electronics Integration:

Challenges lie in the research and development of integrating thin film electronics into packaging technologies. This integration is pivotal for temperature tracking and monitoring perishable goods, although performance concerns remain.

Smart Packaging and Recycling Challenges:

Waste generated from smart packaging presents a significant recycling challenge. Government policies exist, but practical recycling solutions for certain packaging types are elusive. Addressing this challenge involves advancing research in waste treatment and recycling or seeking biodegradable materials for sensor and communication functionalities.

Enhancing Food Packaging Across the Supply Chain:

Enhancements in packaging throughout the food supply chain are imperative. Reliable sealing, regulations for damaged goods during transportation, and innovative approaches for end-of-life food processing are areas requiring further research and improvement.

Meeting Consumer Information Needs:

Consumers increasingly demand information embedded in packaging. This necessitates smarter packaging solutions to provide data on product origin, conditions during transport, safety instructions, and more. Thin film devices, visual safety instructions, and drug delivery systems based on smart packaging technology are poised to meet these demands while increasing health services and patient safety.

OPPORTUNITIES

Nanotechnology’s Role in Safe Packaging:

Nanotechnology is set to play a vital role in addressing safety concerns within packaging. The development of advanced packaging materials, ensuring both suitability and safety, is a significant opportunity. These materials are designed to control the release of active agents in conjunction with sensors embedded within the packaging system.

The Industrial Internet of Things (IIoT):

The IIoT concept aims to establish a globally interconnected network for connecting objects to the cyber-physical world. It enables tracking and control of devices equipped with sensors and actuators. For instance, objects equipped with RFID tags in the packaging can be effectively tracked from the manufacturer to the customer. This integration has the potential to significantly reduce losses in the shipping industry.

Real-time Capabilities and Cyber-Physical Systems (CPS):

Enhancing packaging technologies involves monitoring, managing, and controlling goods’ conditions in real time. This capability has a substantial impact on food safety, consumer well-being, and waste reduction. It necessitates the establishment of a reliable IIoT infrastructure and the incorporation of Information and Communication Technologies throughout the entire supply chain. The result is the creation of cyber-physical production and delivery networks at both vertical and horizontal levels. Artificial Intelligence is expected to play a more prominent role in real-time adjustments and data-driven decision support.

Cybersecurity Challenges:

Despite numerous emerging technologies, a major concern is cybersecurity. Existing internet technologies face cybersecurity and data privacy issues that pose significant challenges. If left unaddressed, these challenges could hinder the full potential of smart packaging in the context of Industry 4.0. The current Internet security landscape is characterized by complex, evolving, and fast-paced cyberattacks. Effective defines strategies must combine preventive measures with autonomic detection and response techniques to create robust cybersecurity systems.

New Business Models:

The digitization of the smart packaging sector necessitates the development of new business models to capitalize on emerging opportunities. Customers seek experiences, leading to a shift from traditional products to product- service-systems. This transformation challenges conventional value chains and business models, with big data and digitization already exerting pressure. Successful models are expected to align technological advancements with innovative business strategies. The manufacturing sector’s strong interest in big data analytics underscores the dominance of data-driven business opportunities and models in the evolving smart packaging landscape.