Technological Advancements in Flexible Packaging: Shaping the Future of Packaging

The packaging industry has witnessed rapid evolution over the past few decades, with flexible packaging emerging as a frontrunner due to its versatility, sustainability, and cost-effectiveness. Powered by technological advancements, flexible packaging has transformed how products are packaged, stored, and consumed, catering to the demands of an ever-evolving market.

From smart materials to digital printing, the innovations in flexible packaging are paving the way for a more efficient and sustainable future. Here’s an exploration of the most groundbreaking advancements in this sector.

Smart and Intelligent Packaging: Beyond Basic Protection

Modern consumers expect packaging to do more than protect a product—it must communicate, interact, and enhance the user experience. Smart packaging technologies, such as time-temperature indicators (TTIs) and QR codes, have made this possible.

- Freshness Sensors: Companies like Thinfilm are integrating freshness sensors in flexible packaging to monitor food spoilage in real-time, offering consumers a reliable way to check product quality.

- Interactive QR Codes: Nestlé uses QR codes on flexible packaging to share detailed nutritional information and recipes, engaging customers digitally.

Benefits:

- Real-time monitoring of product conditions.

- Enhanced consumer engagement and transparency.

- Reduction in waste through improved inventory management.

Sustainable Materials: Reducing Environmental Impact

Sustainability has become a driving force in packaging innovation. To address environmental concerns, flexible packaging has embraced biodegradable, recyclable, and compostable materials.

- Plant-Based Plastics: Companies like TIPA have developed compostable films for food packaging, providing an eco-friendly alternative to traditional plastics.

- Mono material Films: Dow’s INNATETM technology uses single-layer recyclable films to simplify recycling without compromising durability.

Benefits:

- Lower carbon footprint compared to rigid packaging.

- Reduction in plastic pollution through biodegradable solutions.

- Alignment with global sustainability goals and consumer preferences.

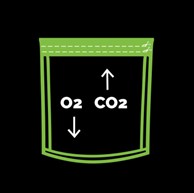

Barrier Technologies: Extending Shelf Life

One of the critical challenges in flexible packaging is maintaining product freshness while reducing material usage. Advanced barrier technologies have addressed this by offering superior protection against oxygen, moisture, and UV light.

- High-Barrier Films: Amcor’s AmLite Ultra Recyclable film provides a lightweight yet robust barrier for food and pharmaceutical products, extending shelf life and reducing waste.

Benefits:

- Prolonged product freshness and quality.

- Minimized food wastage across the supply chain.

- Improved packaging efficiency with thinner yet stronger materials.

Digital Printing: Revolutionizing Customization

Gone are the days of mass-produced, identical packaging. Digital printing has introduced unprecedented flexibility and customization in packaging design, allowing brands to connect with their audience on a personal level

- Coca-Cola’s “Share a Coke” campaign leveraged digitally printed flexible packaging to customize labels with popular names, driving consumer engagement and boosting sales.

Benefits:

- Shorter lead times and reduced waste.

- High-quality, vibrant designs with intricate details.

- Cost-effective for small batch runs and personalized campaigns.

Lightweighting: Doing More with Less

Digital twins—a virtual replica of a physical system—have revolutionized design and maintenance in packaging machinery. They allow manufacturers to simulate, predict, and optimize performance without halting production.

Example:

Tetra Pak uses digital twins to test new designs in a virtual environment, cutting down on prototyping costs and time.

Benefits:

- Enhanced R&D: Simulate designs to foresee performance bottlenecks.

- Real-Time Monitoring: Digital twins reflect live machine operations.

- Cost Efficiency: Prevents production losses during testing phases.

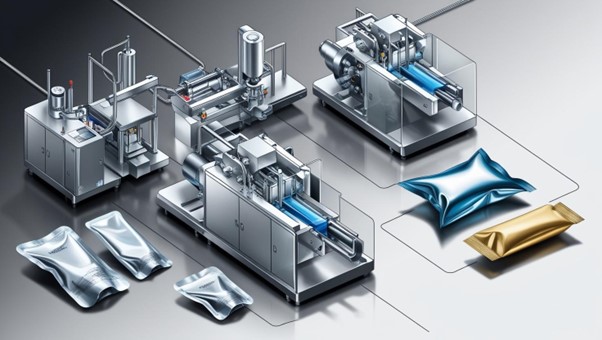

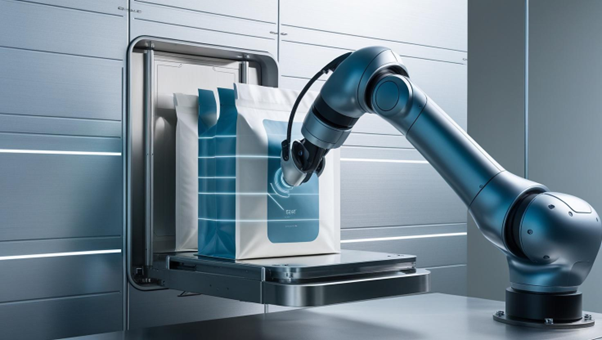

Automation and AI in Flexible Packaging

Automation and artificial intelligence (AI) have redefined how flexible packaging is manufactured and inspected. From high-speed production lines to error detection systems, technology ensures precision and scalability.

- Robotic Packaging Lines: Companies like ABB use robotics to automate the packaging process, increasing speed and reducing human error.

- AI-Powered Inspection: Systems like EyeC detect minute defects in printed packaging, ensuring consistent quality.

Benefits

- Faster production with minimal downtime.

- Improved product quality and consistency.

- Reduced operational costs and waste.

E-Commerce-Ready Packaging: Built for the Digital Shopper

As e-commerce continues to dominate retail, flexible packaging has adapted to meet the unique challenges of online shopping.

- Amazon’s Frustration-Free Packaging initiative encourages the use of flexible, recyclable materials that protect products during shipping while being easy for consumers to open.

Benefits:

- Reduced shipping costs due to lightweight materials.

- Enhanced durability to withstand transit conditions.

- Consumer-friendly designs that minimize waste.

Conclusion: A Future-Ready Industry

The technological advancements in flexible packaging signify a paradigm shift, making it an indispensable part of modern supply chains. From sustainable materials to intelligent designs, these innovations cater to the demands of a dynamic market while addressing environmental concerns.

Flexible packaging is no longer just a convenience but a solution for a sustainable, efficient, and customer-centric future. Companies that embrace these advancements will stay competitive and lead the way toward a greener and smarter world.

References –

https://www.drupa.com/en/Media_News/drupa_blog/Sustainability/Navigating_the_Future_of_Packaging_A_Deep_Dive_into_Substrate_Technologies

https://www.idtechex.com/en/research-report/smart-and-intelligent-packaging-2020-2030/691