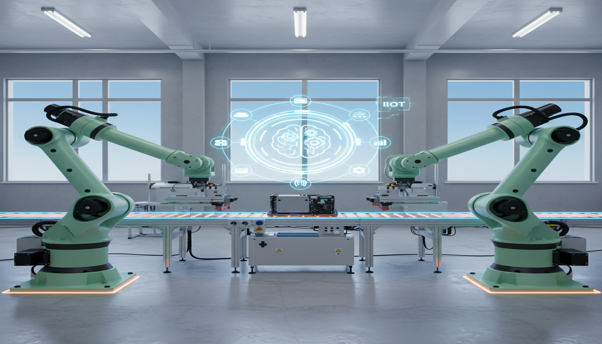

Experience the future of computing where processing power meets data at its source. In packaging production, we

revolutionize operations by seamlessly processing data directly on machines and devices along the production line. Say goodbye to the constraints of centralized cloud servers and embrace the agility of edge computing

In the realm of cutting-edge technology, envision a landscape where data activities unfold seamlessly at the source, bypassing the constraints of centralized networks. Embrace the transformative power of edge computing, optimizing the

performance of equipment, IoT devices, and applications by strategically placing computing capabilities right at the network

edge where data is born. Experience a paradigm shift that brings efficiency to the forefront of data processing

KEY BENEFITS OF EDGE COMPUTING

- Reduced Latency: By processing data locally, edge computing eliminates the need for data to travel long distances to the cloud, which can significantly reduce latency. This is crucial for real-time applications, such as quality control or machine vision, where fast decision-making is critical.

- Increased Bandwidth: By offloading data processing from the cloud, edge computing frees up valuable bandwidth for other essential tasks. This is specially beneficial in production environments where large amounts of

data are generated. - Improved Security: Edge computing can improve data security by reducing the amount of sensitive data that needs to be transmitted over the internet. This is because certain data can be processed and analysed

locally without ever leaving the production environment. - Enhanced Reliability: By decentralizing the processing power, edge computing can make production operations more resilient to network outages or disruptions. This is because even if the cloud connection is unavailable, local processing can still continue.

Unlocking the Potential of Edge Computing in the Realm of Packaging Production

- Machine Vision: Cameras can be used to inspect products for defects on the production line. Edge computing allows these images to be analysed locally in real-time, so that defective products can be rejected

immediately. - Predictive Maintenance: Sensors can be attached to machines to monitor their performance and predict potential failures. Edge computing allows this data to be analysed locally, so that maintenance can be scheduled before a breakdown occurs.

- Process Optimization: Data from various sources in the production line can be collected and analysed in real-time to identify areas for improvement. This information can be used to optimize various parameters, such as machine settings or material usage.

Harnessing the Power of Edge Computing for Industrial IoT Solutions

- Driving Automation: Integrating edge computing into equipment and processes on the shop floor eliminates delays, enabling real-time automation and paving the way for a lights-out factory with reduced human intervention.

- Implementing Predictive Maintenance in Industry 4.0: Utilizing edge computing, maintenance procedures for Industrial IoT devices in smart facilities become fully automated. This ensures optimal performance by

allowing devices to autonomously identify and address recharging needs.